Major Advance: Reversing Catalyst Ripening at Hefei Light Source

More than 90% of industrial chemical processes rely on the participation of catalysts. Throughout the reaction, catalysts are not static; many supported nanometal catalysts undergo sintering after a period of use, resulting in the emergence of unusually large particles among originally uniform nanometal particles. The transformation from small to large metal particles often follows the Ostwald ripening mechanism. For years, the “Ostwald ripening” effect has been like an unbreakable “curse”, causing irreversible damage to catalyst performance. The number of active sites in sintered catalysts sharply decreases, leading to a “precipitous decline” in catalytic performance. To counter this “degradation”, common industrial practices include increasing catalyst loading severalfold or suspending production to regenerate or replace the catalyst, incurring significant costs.

To address this challenge, the team of Professor Xiao Fengshou and Researcher Wang Liang from Zhejiang University designed a dealuminated Beta zeolite support for copper nanoparticle catalysts by controlling the dynamic structural evolution path of metal species during traditional sintering. This support incorporates numerous “silanol nest” sites within its structure, successfully reversing the catalyst “ripening” process.

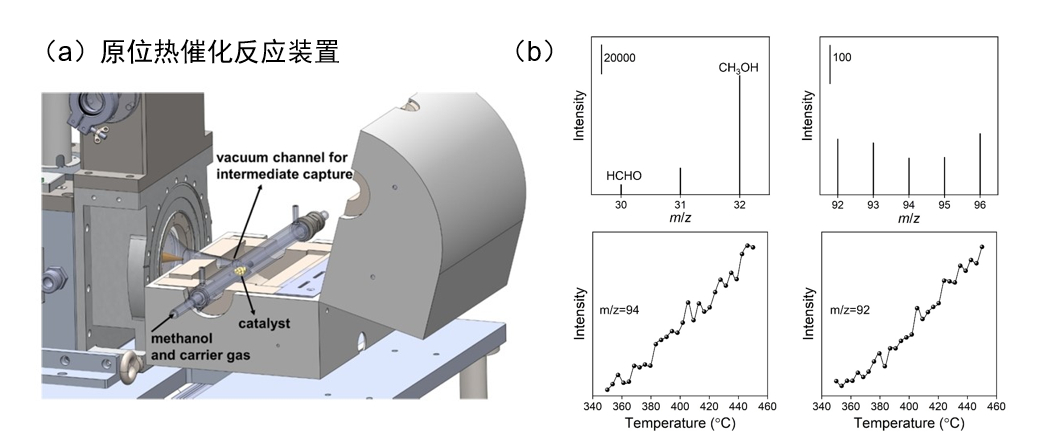

In their mechanistic study of the “ripening” process, the team utilized the in-situ thermal catalysis reaction device (Fig. 1a) combined with synchrotron vacuum ultraviolet photoionization mass spectrometry (SVUV-PIMS) at the Beamline of Atomic and Molecular Physics (BL09U) at Hefei Light Source, to investigate possible intermediates formed during copper atom migration, such as (CHO)Cu1* (m/z = 92, 94), (CH2O)Cu1* (m/z = 93, 95), and (CH3O)Cu1* (m/z = 94, 96). The results indicate the presence of Cu1-related intermediates during migration. During methanol treatment, the signal intensities of these intermediates gradually increased with rising temperature (Fig. 1b), related to their easier formation and faster release at higher temperatures. These findings align well with the Ostwald ripening process chemically triggered by metal sintering. This research provides new insights for the design and development of durable catalysts.

Fig. 1. (a) Schematic diagram of the in-situ thermal catalysis reaction device. (b) Species measured by SVUV-PIMS and their variation trends as a function of reaction temperature.

The related findings were published under the title “Dealuminated Beta zeolite reverses Ostwald ripening for durable copper nanoparticle catalysts” in the renowned international academic journal 《Science》.

Link to the paper:https://www.science.org/doi/10.1126/science.adj1962.

Back