Three-dimensional reconstruction of solid oxide fuel cell electrode using nano X-ray tomography

Energy and environment conjunctures are problems that need to be solved imminently along with the progress of society and industry. Solid oxide fuel cells (SOFCs) as a new and clean energy have attracted much attention recently because of their high-energy conversion efficiency, environmental safety, and fuel flexibility and thus have potential value to be used in industry power and transportation systems.

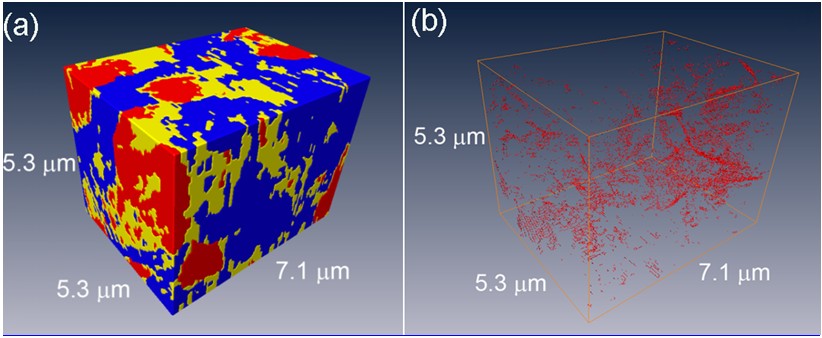

The research group of Prof. Tian in National Synchrotron Radiation Laboratory collaborated with the research group of Prof. Wang in Hefei National Laboratory for Physical Sciences at Microscale to develop a new method for nondestructive imaging the three dimensional (3D) micro structural of SOFC electrode. Two 3D scans were collected in absorption-contrast mode below (8300 eV) and above (8380 eV) the Ni K-shell absorption edge. The three phases (Ni, YSZ and pore) in anode could be identified and the 3D volume was segmented and then used to calculate several key parameters, such as volume fraction, surface area, three-phase boundary length. These calculated parameters are critical for understanding the electrochemical conversion efficiency, studying the electrode reliability, and improving manufacturing processes.

(a) the 3D rendering of the anode reconstruction data, and (b) space distribution of the TPB

(a) the 3D rendering of the anode reconstruction data, and (b) space distribution of the TPB

The results have been published on Journal of Power Source (2011, 196: 1915) and Journal of Synchrotron Radiation (2010, 17: 782).

Commercial applications of SOFCs for stationary power sources require their stable performance over long periods of time (>40,000 h); therefore, it is of great importance to understand the degradation mechanism of SOFCs to improve the operation time and optimize the performance.

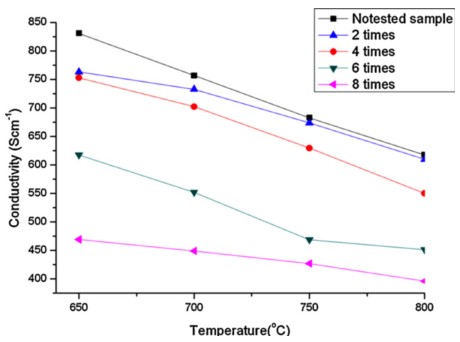

The two research groups teamed up to explore the micro structural changes of SOFC electrode during thermal cycle and further link it to the performance of SOFC. The results of this research have indicated that the agglomeration of nickel particles occurs in Ni-YSZ anodes after multiple thermal cycles and the average diameter of Ni grain increases. The agglomeration of the nickel particles mainly be caused by the migration of Ni during thermal treatment and resulted in changes in the connectivity of the Ni phase, which can affect the electrical conductivity of the Ni-YSZ anode. By measuring the conductivity of all of the samples studied in this paper, it was found that the conductivity decreased during thermal cycling. In addition, the decrease in the connected TPB length may lead to poorer performance due to a decrease in the number of electrochemically active sites.

Variation of conductivity with thermal cycle time and the conductivity of anode

The results have been published on the top journal in energy science: Journal of Power Source (196 (2011) 10601– 10605).

QQ截图20131115155741.jpg

Back